Thin-film pressure sensors, known for their high sensitivity, lightweight, and flexibility, have shown vast application potential in the design of multi-level switches. These sensors can achieve multi-level switching based on different pressure detections and are widely used in electronic devices, household appliances, and industrial control systems.

Key Advantages

Accurate Pressure Sensing: Thin-film pressure sensors can precisely detect applied pressure and switch levels based on different pressure values. This high-precision pressure sensing ensures the accuracy and reliability of level switching.

Thin and Lightweight Design: The thin and lightweight characteristics of thin-film pressure sensors allow for easy integration into various devices without adding bulk or weight. This design advantage is especially significant in applications where space and weight savings are crucial.

High Sensitivity: Thin-film pressure sensors are highly sensitive and can detect minute pressure changes, enabling fine multi-level switching. This high sensitivity provides users with better tactile feedback and control during operation.

Durability and Stability: Made from high-quality materials, thin-film pressure sensors are durable and stable. They maintain excellent performance even under long-term use or harsh environments.

Application Examples

- Electronic Device Control:

- Thin-film pressure sensors can be used in smartphones, tablets, and other electronic devices for multi-level volume control, screen brightness adjustment, and more, providing an intuitive and convenient user experience.

- Household Appliances:

- In household appliances, thin-film pressure sensors can be used for multi-level fan speed adjustment, temperature control in air conditioners, and other settings, enhancing user comfort and control precision.

- Industrial Control:

- In industrial control systems, thin-film pressure sensors can be applied for multi-level pressure regulation, liquid level control, and more, offering precise control and adjustment functions, thereby improving production efficiency and safety.

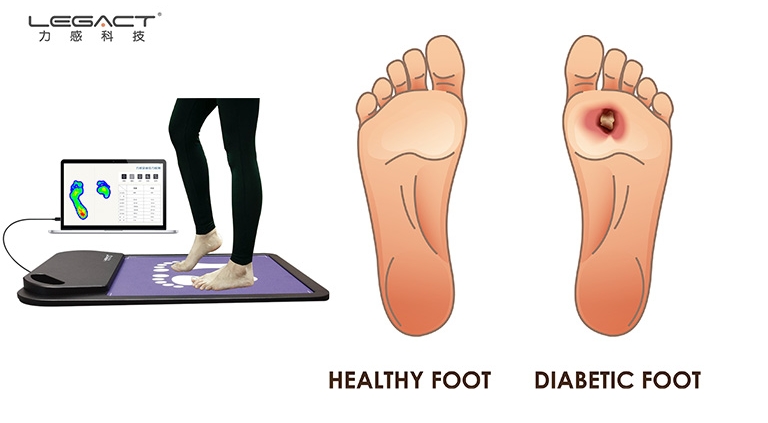

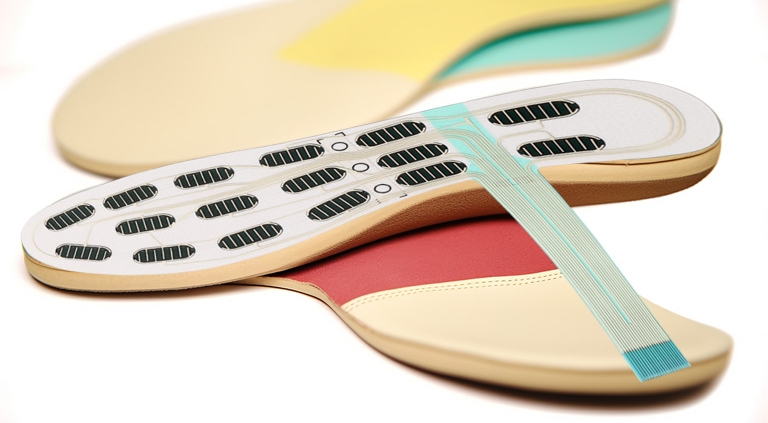

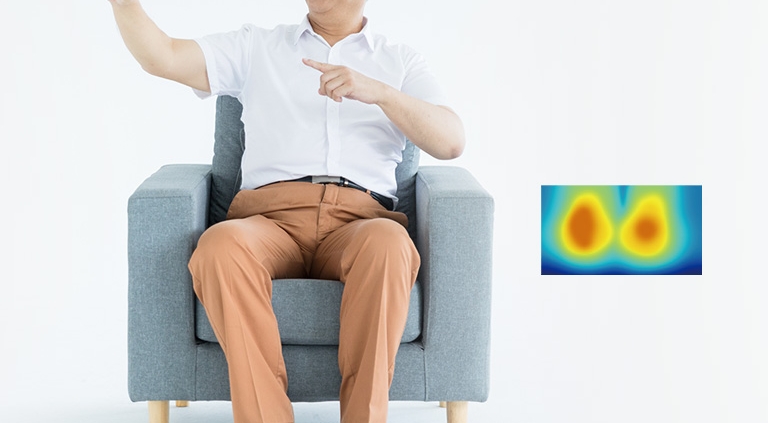

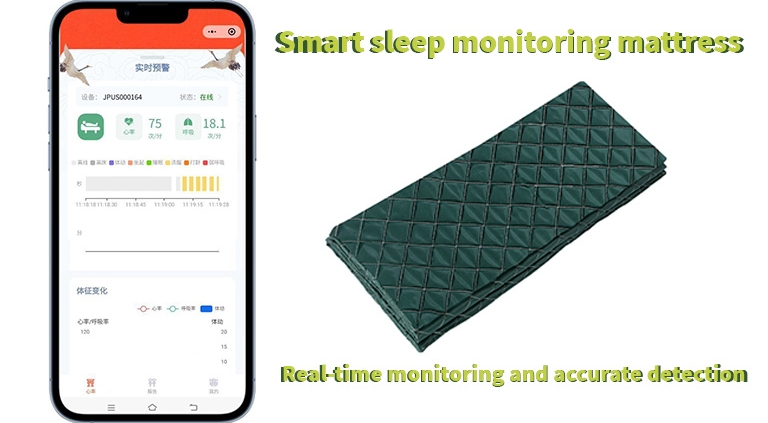

- Medical Devices:

- In medical devices, thin-film pressure sensors can be used for multi-level flow control, pressure adjustment, and other functions, ensuring the accuracy and safety of medical operations, and providing better patient care.

Conclusion

The application of thin-film pressure sensors in multi-level switches provides high-precision and high-sensitivity solutions for controlling and adjusting various devices. Through their thin design and accurate pressure sensing, thin-film pressure sensors enhance device performance and user experience while expanding their application range. As technology continues to advance, thin-film pressure sensors will play an increasingly important role in more fields, offering strong support for the intelligent and precise control of various devices.