Thin-film pressure sensors, known for their high sensitivity, lightweight, and flexibility, are widely used in various pressure distribution detection products. These sensors can accurately measure and analyze the pressure distribution on different surfaces, providing reliable data support for medical, sports, industrial, and other fields. Below are the main applications and advantages of thin-film pressure sensors in pressure distribution products.

Precise Pressure Measurement

Thin-film pressure sensors can precisely detect small pressure changes on surfaces, making them excellent for applications requiring high-precision pressure measurements. For example, in the medical field, thin-film pressure sensors can monitor the pressure distribution on a patient’s bed to help prevent the development of pressure ulcers.

High Sensitivity and Response Speed

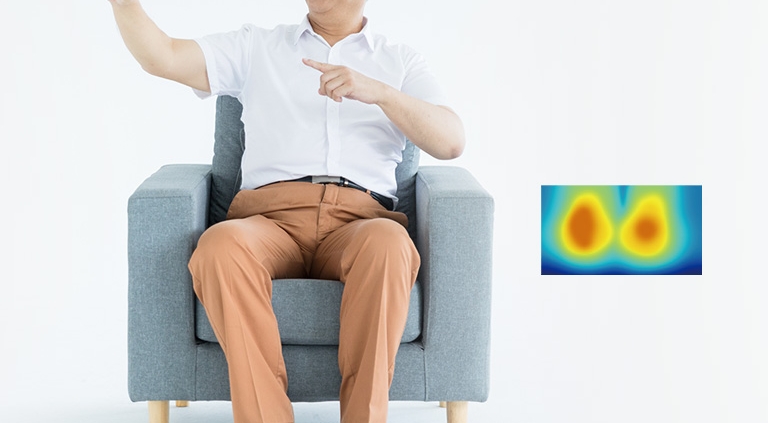

The high sensitivity and fast response capability of thin-film pressure sensors allow them to capture pressure changes in real-time. This is particularly important for sports monitoring and ergonomic research. By monitoring pressure distribution during physical activity, athletes can optimize their posture and reduce the risk of injury.

Flexibility and Adaptability

The lightweight and flexible design of thin-film pressure sensors enables them to adapt to various complex surfaces and be easily embedded in different devices without affecting their form. For instance, in smart insoles, thin-film pressure sensors can accurately record foot pressure distribution, helping users understand their gait and posture.

Data Analysis and Application

The data collected by thin-film pressure sensors can be thoroughly analyzed using software, providing support for various applications. In the industrial sector, thin-film pressure sensors can monitor the pressure distribution in machinery, helping to optimize design and maintenance, thereby improving efficiency and safety.

Application Examples

- Medical Monitoring:

- Anti-Decubitus Mattresses: Monitor pressure distribution on bedridden patients to prevent pressure ulcers.

- Rehabilitation Therapy: Record and analyze patient pressure distribution to create personalized rehabilitation plans.

- Sports Analysis:

- Smart Insoles: Real-time monitoring of foot pressure distribution to help runners optimize their running posture and prevent injuries.

- Fitness Equipment: Analyze user pressure distribution to optimize training effectiveness.

- Industrial Applications:

- Machinery Monitoring: Monitor pressure distribution in operating equipment to detect and address abnormalities promptly.

- Product Design Optimization: Use pressure distribution data to optimize product design, enhancing durability and performance.

Conclusion

Thin-film pressure sensors in pressure distribution detection products provide accurate and reliable data support for medical, sports, industrial, and other fields. Their high sensitivity, fast response, flexibility, adaptability, and detailed data analysis capabilities make them essential tools for pressure distribution measurement. As technology advances, thin-film pressure sensors will further expand their application range, offering stronger support and more innovative possibilities for various industries.