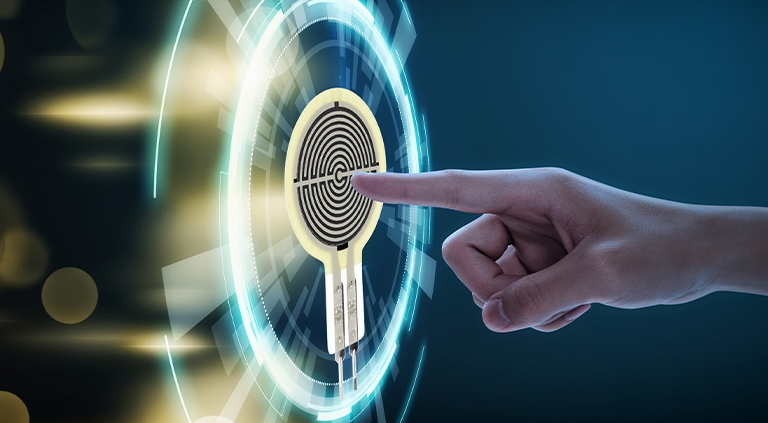

Thin-film pressure sensors are widely used in various electronic devices and systems due to their high sensitivity, lightweight, and flexibility. These sensors operate based on the principle of force, detecting and measuring external pressure changes and converting them into electrical signals. This article will explore the role of force in thin-film pressure sensors, their technical advantages, and broad applications.

Principle of Force

The core component of a thin-film pressure sensor is its sensing membrane, which is made from pressure-sensitive material. When an external force is applied to the sensing membrane, it deforms, causing changes in the internal resistance or capacitance of the membrane. This change is converted into an electrical signal through a circuit, enabling the detection and measurement of pressure.

Operational Steps:

- Application of External Force: Pressure is applied to the surface of the membrane.

- Membrane Deformation: The sensing membrane deforms under pressure.

- Change in Electrical Parameters: The deformation causes changes in the internal resistance or capacitance of the membrane.

- Signal Conversion: These changes are converted into electrical signals through a circuit.

- Data Output: The resulting electrical signals are output for analysis and application.

Technical Advantages

High Sensitivity: Thin-film pressure sensors can accurately detect minor pressure changes, making them suitable for applications requiring high precision measurements.

Lightweight and Flexible: Their thin and flexible design allows for easy integration into various devices without affecting the size and appearance.

High Reliability: These sensors are durable and have a long service life, capable of stable operation in diverse environments.

Low Power Consumption: Their low power consumption makes thin-film pressure sensors ideal for portable electronic devices, extending battery life.

Application Scenarios

1. Medical Devices

In medical devices, thin-film pressure sensors can monitor critical indicators such as patient weight, respiration, and blood pressure. Their high sensitivity and reliability ensure data accuracy and device stability.

2. Sports Monitoring

Thin-film pressure sensors can be integrated into smart insoles or fitness trackers to monitor an athlete’s gait and pressure distribution, helping to optimize training plans and improve performance.

3. Touch Devices

In smartphones and tablets, thin-film pressure sensors provide precise touch feedback, enhancing user experience.

4. Industrial Control

Thin-film pressure sensors are widely used in industrial automation to monitor and control pressure changes in production lines, ensuring safety and efficiency in the manufacturing process.

Application Examples

- Smart Mattresses: Embedded thin-film pressure sensors in mattresses can monitor the weight distribution and posture of sleepers, providing personalized sleep data analysis and suggestions.

- Smart Insoles: Insoles with built-in thin-film pressure sensors can record gait and foot pressure, helping runners improve their running posture and prevent injuries.

- Blood Pressure Monitors: Thin-film pressure sensors are used in electronic blood pressure monitors to provide accurate blood pressure measurements, helping users monitor their health in real-time.

- Industrial Pressure Monitoring: In the industrial field, thin-film pressure sensors are used to monitor pressure changes in hydraulic and pneumatic systems, ensuring normal operation and safe production.

Conclusion

Thin-film pressure sensors, capable of accurately detecting and measuring external pressure changes, show broad application prospects in medical, sports, touch devices, and industrial control fields. With ongoing technological advancements, thin-film pressure sensors will play an increasingly important role, providing more precise and reliable pressure detection solutions for various applications. By effectively utilizing thin-film pressure sensors, we can better understand and control pressure changes, enhancing device performance and user experience.