With the changing lifestyle of modern society, our sitting habits are becoming increasingly unhealthy. Prolonged periods of poor sitting posture may lead to spinal issues, neck discomfort, sciatica, and other health problems. In such a context, the smart pressure cushion emerges, providing us with a novel solution. So, what are the functions of a smart pressure cushion? Let’s explore.

1. Posture Improvement and Enhanced Comfort

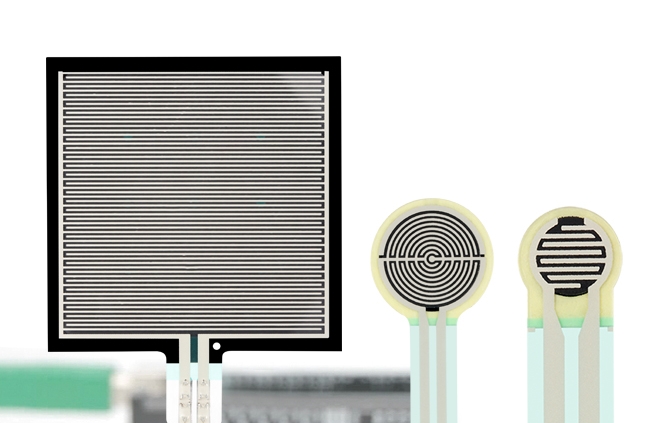

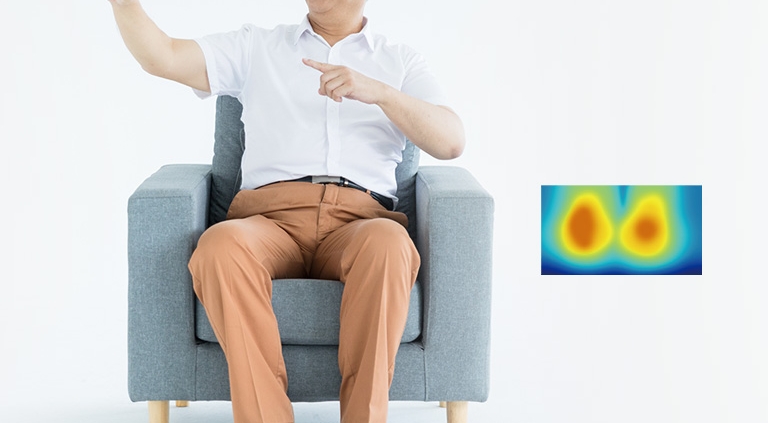

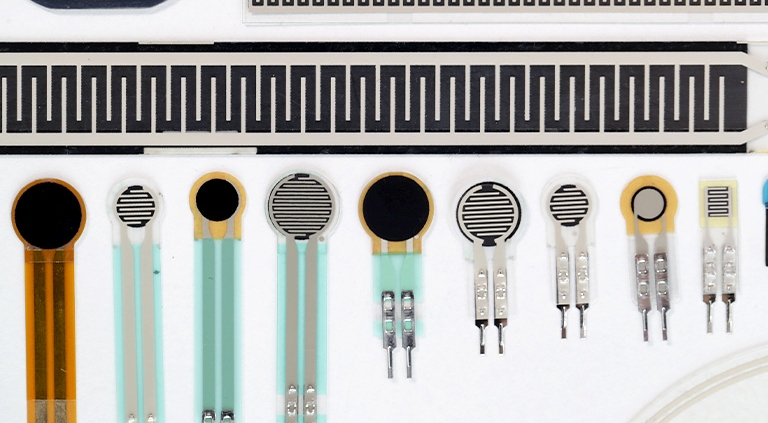

Utilizing advanced sensor technology, smart pressure cushions can monitor our sitting posture in real-time and provide feedback based on pressure distribution. By analyzing this data, we can understand whether our sitting habits are correct and whether there are areas of excessive pressure concentration. With feedback from smart pressure cushions, we can adjust our posture in a timely manner, improve sitting habits, and consequently increase comfort, reducing the occurrence of back pain and other issues.

2. Prevention of Sitting-Related Diseases

Prolonged incorrect sitting posture may lead to various sitting-related diseases, such as spinal issues, neck discomfort, sciatica, and more. Smart pressure cushions can provide timely reminders to adjust our posture by monitoring our sitting posture in real-time, preventing the occurrence of these potential health problems. This is particularly important for those who need to sit at their desks for long periods, such as office workers.

3. Health Management in the Workplace

In the workplace, prolonged sitting is common, and poor sitting habits may negatively impact employees’ health, thereby affecting work efficiency and productivity. Smart pressure cushions can be applied to office chairs to provide employees with sitting posture monitoring and adjustment suggestions, helping them maintain good working posture, and improve work comfort and efficiency.

4. Rehabilitation Therapy Assistance

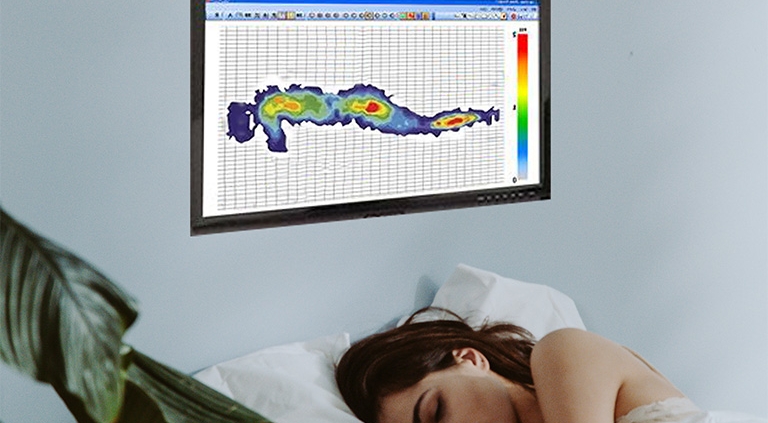

In rehabilitation therapy, correct sitting posture is crucial to the rehabilitation process. Smart pressure cushions can help rehabilitation professionals monitor patients’ sitting posture, ensuring that they maintain the correct posture during the rehabilitation process, thereby accelerating the rehabilitation process.

5. Optimization of Sports Seats

In the fields of car seats, wheelchairs, and other seats, smart pressure cushions can also play an important role. By monitoring users’ sitting posture and pressure distribution, smart pressure cushions can help design seats that are more ergonomic, improving sitting comfort and health.

In summary, smart pressure cushions can not only improve our sitting habits and comfort but also prevent sitting-related diseases, improve health management in the workplace, assist in rehabilitation therapy, and optimize sports seat design. They provide us with an effective way to manage sitting health, promoting physical health and comfort. Let’s embrace the revolution of comfort and health brought by smart pressure cushions!