1. Introduction

Resistive thin-film pressure sensors, known for their simple structure and high sensitivity, have gained widespread use in medical monitoring devices. These sensors specifically convert physical pressure changes into changes in resistance, particularly excelling in pulse monitoring applications. This article aims to explore the working principles and applications of resistive thin-film pressure sensors in pulse detection.

2. Working Principle of Resistive Thin-Film Pressure Sensors

Resistive thin-film pressure sensors operate based on the piezoresistive effect, where the resistance of the sensor material changes under applied pressure. Typically comprising conductive materials and an elastic substrate, the sensor experiences a change in the contact area or path of the conductive material under pressure, leading to a variation in resistance. By measuring this resistance change, the sensor can accurately monitor periodic biological pressure fluctuations like the pulse.

3. Applications in Pulse Detection

The pulse, a physiological phenomenon reflecting cardiac activity through blood pulsation in the vessels, can be effectively monitored with resistive thin-film pressure sensors in various ways:

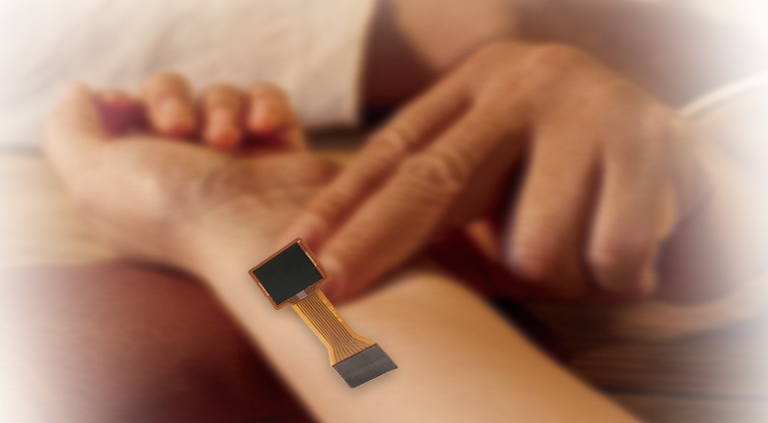

- Wearable Devices: Integrated into watches, bracelets, or other health monitoring gadgets for real-time tracking of an individual’s heart rate and heart rate variability. Sensors can be designed as patches directly adhered to the skin or embedded into clothing and accessories to provide continuous health tracking.

- Clinical Monitoring: In hospital settings, resistive thin-film pressure sensors are used to monitor patients’ physiological parameters, especially cardiac health. They can be integrated into bed monitoring systems to help medical staff assess patients’ cardiovascular function and blood flow status using pulse readings.

- Health Assessment Systems: For home health management, resistive thin-film pressure sensors serve as manual or automatic monitoring tools, enabling individuals to check their pulse without professional medical equipment. Such systems are particularly beneficial for chronic patients and the elderly, providing a simple method to regularly check cardiovascular health.

4. Challenges

- Signal Interference: Body movement, external vibrations, and non-physiological pressure changes can cause false signals, necessitating advanced algorithms to distinguish physiological signals from interference.

- Environmental Factors: Temperature and humidity changes can affect sensor performance, requiring consideration during design and the development of corresponding compensation technologies.

- Long-term Stability: The materials and design of the sensor must withstand prolonged mechanical stress and environmental factors to ensure that long-term usage does not compromise accuracy and reliability.

5. Future Prospects

With technological advancements and increasing demand for health monitoring, the application range of resistive thin-film pressure sensors is expected to expand further. Future research and development are likely to focus on improving the precision, stability, and user experience of sensors, better serving the medical and personal health sectors. By integrating AI technology, future pulse monitoring devices will provide more intelligent health data analysis and recommendations, offering robust support for health management.