Array Sensor

Array sensors can be used for pedometers, gait analysis, foot stress analysis, and foot correction analysis

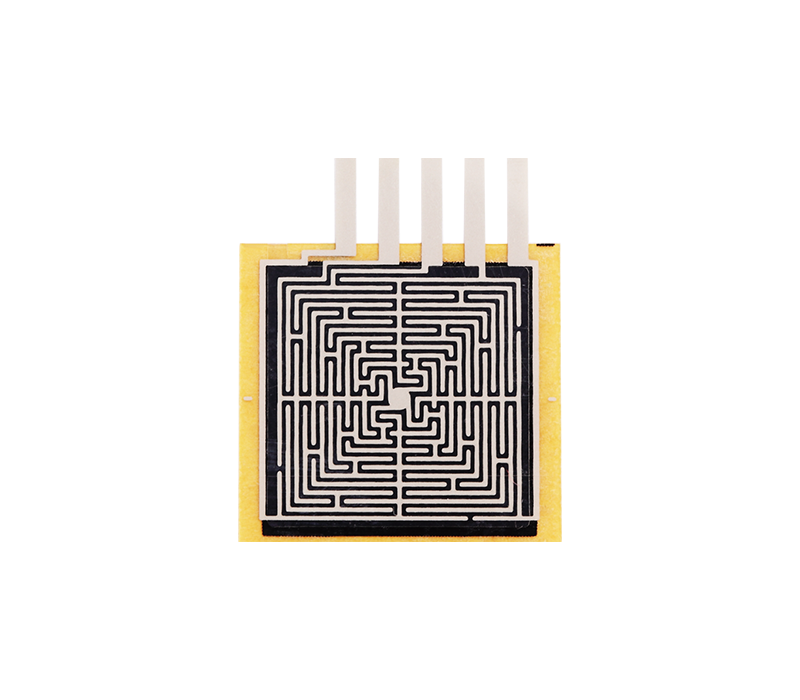

FS-INS-16Z

FS-ARR-4×8-ROT

STANDARD PRODUCT

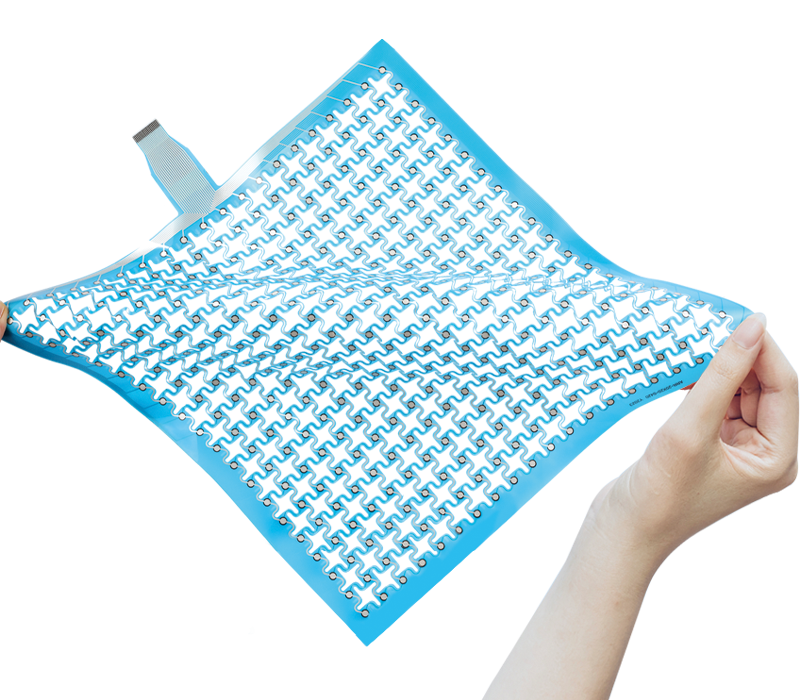

Array Sensor

The array sensor not only possesses the advantages of ordinary array-type sensors,

but also has excellent flexibility, enabling it to conveniently inspect parts with complex surface shapes.

It is widely applied in contact measurement, non-destructive testing, robotics, biomechanics and other fields.

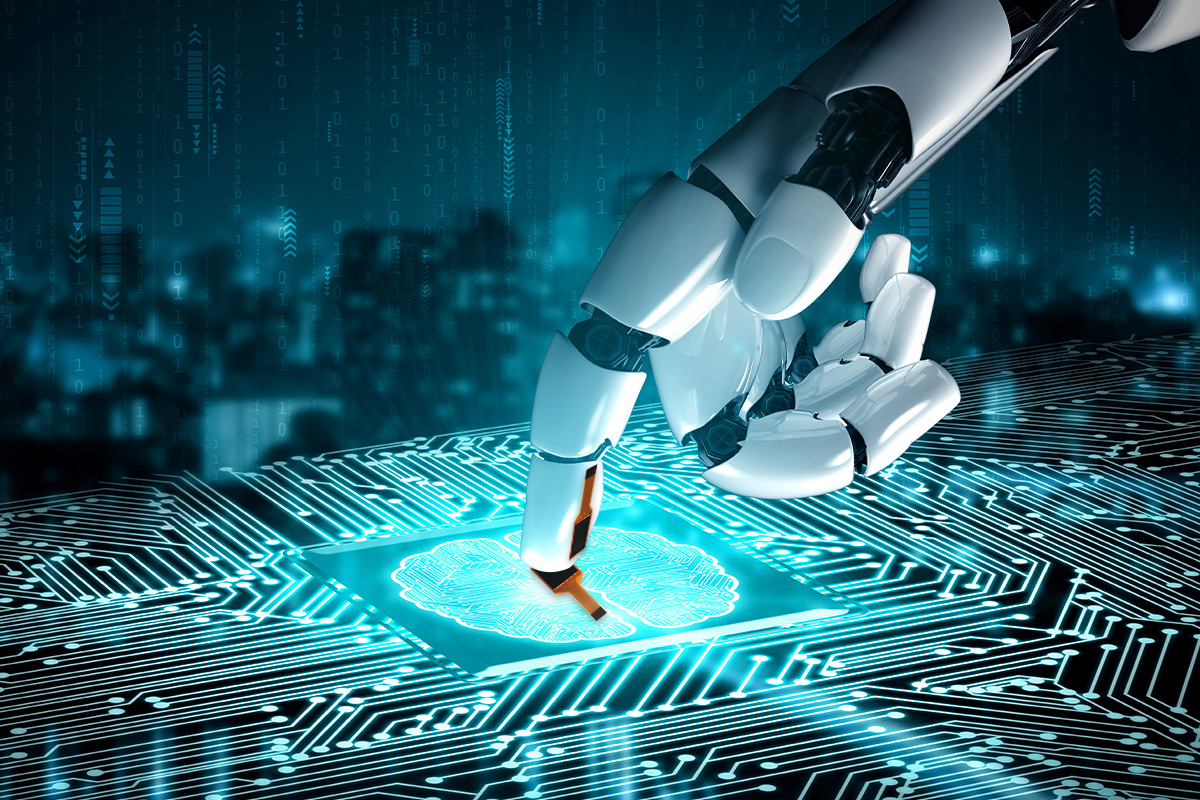

Robot fingers

- Tactile perception and grasping optimization

Real-time detection of pressure distribution on the contacting object through a high-density pressure array, identification of object shape, softness, and surface texture, dynamic adjustment of grasping force to avoid slipping or damage (such as grasping eggs, glass cups). - Adaptive operation

Realize compliant control in complex environments (such as unknown object grasping or dynamic target tracking), combine force feedback to achieve flexible operation like “human-like fingers”. - Safe collaboration

Detect pressure changes during human contact, trigger emergency stop or retraction actions to ensure the safety of human-machine collaboration.

The array-type thin-film pressure sensor endows the robot fingers with precise tactile capabilities, significantly enhancing the grasping reliability and environmental adaptability. It is a core technology in collaborative robots, service robots, and industrial automation.

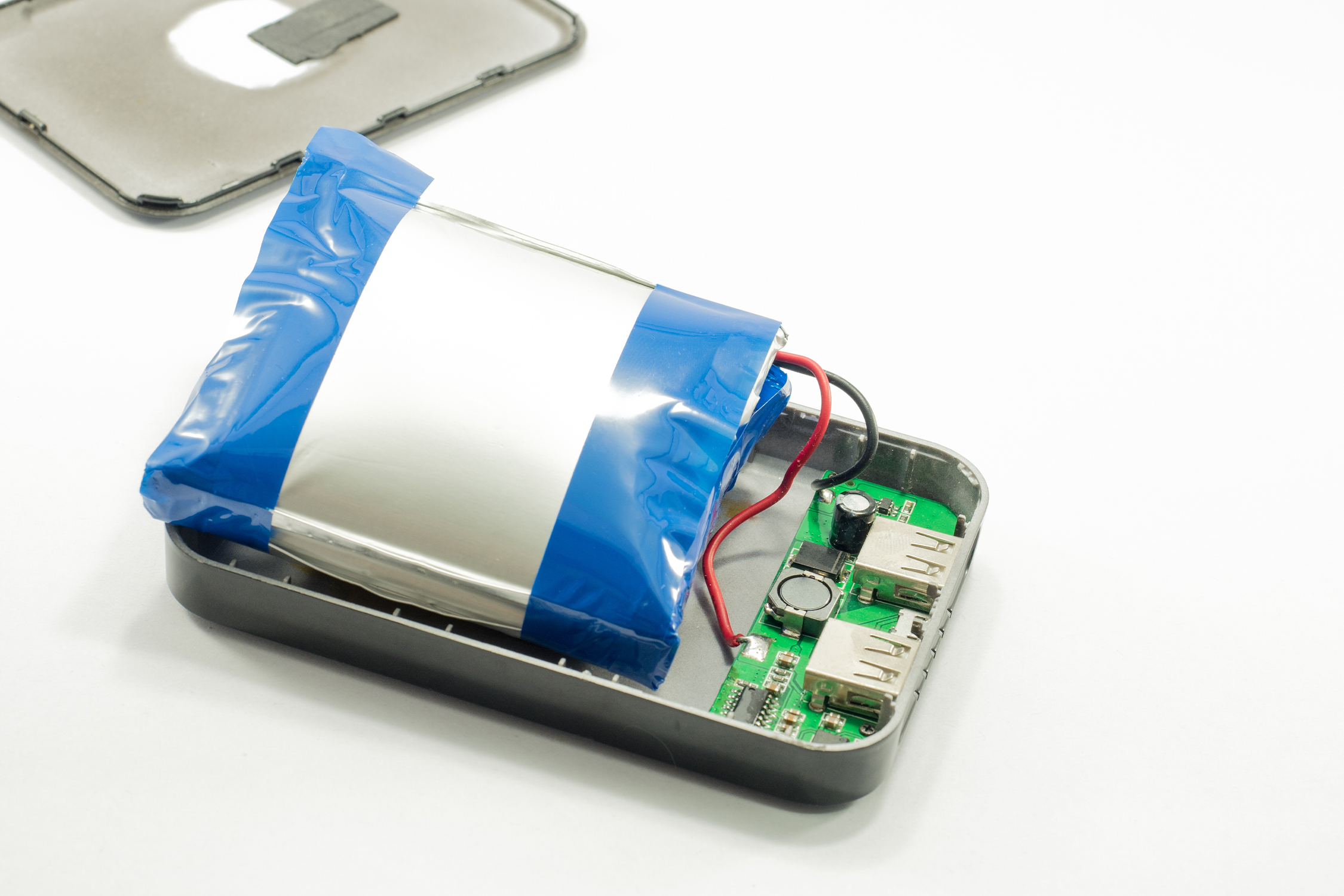

Battery bulge detection

- Real-time expansion monitoring::

Attach flexible pressure sensors to the surface of batteries (such as those in mobile phones and electric vehicle battery packs), detect local expansion and deformation caused by overcharging, aging, or short circuits, and issue warnings when pressure distribution is abnormal. - Life assessment::

Long-term record the expansion patterns during battery charging and discharging cycles, combine algorithms to predict remaining life, and optimize maintenance cycles.

Through non-invasive pressure monitoring technology, the sensor provides active protection for battery safety, reduces the risk of thermal runaway, and also assists in battery health management. It is widely applied in new energy equipment and energy storage systems.

Professional keyboard

- Multi-level pressure sensing::

Pressure sensors are integrated beneath each key, enabling multi-level input from light touches to heavy presses (such as the velocity response of a music MIDI keyboard or the “key travel grading” of an e-sports keyboard). - Dynamic feedback adjustment::

The trigger threshold or feedback intensity is adjusted in real time based on the pressure applied (such as simulating the feel of a mechanical keyboard or the soft trigger in silent mode).

The sensor upgrades the traditional keyboard to an intelligent interactive interface, enhancing input efficiency and immersion through precise force sensing, and has become a core peripheral device in professional fields such as music production, e-sports, and programming.

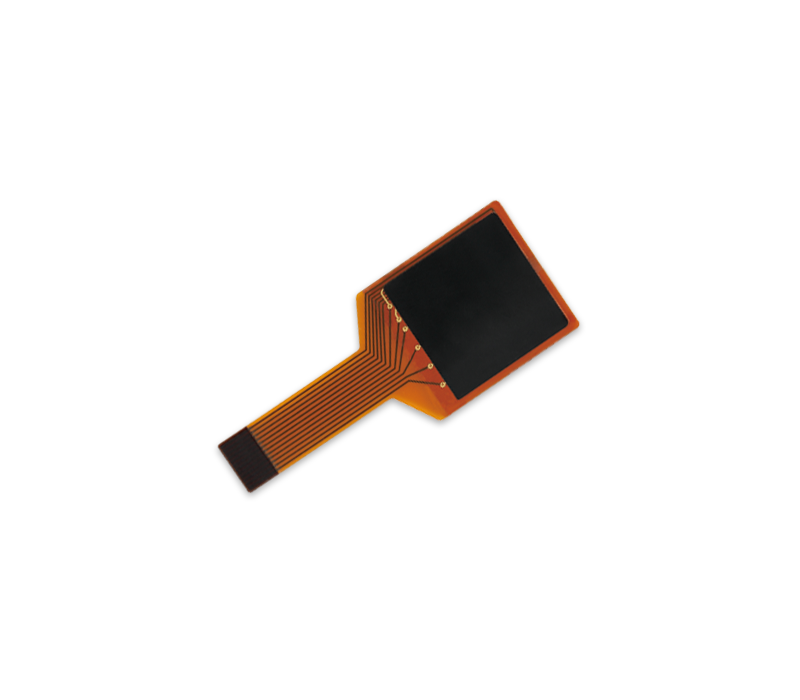

Intelligent Manufacturing

- Assembly quality monitoring::

During processes such as screen alignment on the mobile phone and assembly of precision parts, real-time detection of pressure distribution uniformity is conducted to prevent warping or cracking due to uneven force (such as detecting the glue curing pressure between the OLED screen and the middle frame). - Mechanical arm force control::

Integrated into the end effector of the mechanical arm (such as the grinding head, suction cup), it dynamically adjusts the contact force to achieve high-precision polishing, deburring, or handling of fragile items. - Equipment health management::

Monitoring abnormal contact pressure of production line equipment (such as bearing wear, conveyor belt deviation).

The array-type thin-film pressure sensor, through real-time force feedback and data analysis, drives the intelligent manufacturing to develop towards flexibility and high precision, significantly improving the yield rate and reducing the equipment operation and maintenance costs.

About LEGACT

Product

Contact Us

Only some product parameters are displayed. For more requirements, please contact us.

Technical phone: +8615813728838

Sales phone: +8615814469277

Technical email: denny@film-sensor.com

Sales email: elianexiong@film-sensor.com

.png)