In the field of modern technology, the development of sensor technology has become a key driver of progress in many areas. In the realm of pressure sensors, resistive pressure sensors and piezoelectric pressure sensors are two common types. Although both are used for measuring pressure, they each possess unique advantages and applications. This article will focus on discussing the advantages of resistive pressure sensors over piezoelectric pressure sensors.

First, let’s briefly understand the working principles of these two sensors. Piezoelectric sensors utilize the piezoelectric effect to measure pressure changes. When pressure is applied to the sensor, it generates electric charge, thereby achieving pressure detection. On the other hand, resistive pressure sensors utilize the resistive effect, containing a sensing resistor internally. When pressure is applied to the sensor, the resistance value changes, allowing pressure to be detected by measuring the change in resistance.

Now, let’s examine the advantages of resistive pressure sensors relative to piezoelectric pressure sensors:

- Cost-effectiveness: Resistive pressure sensors are typically more cost-effective than piezoelectric pressure sensors. This is because the manufacturing cost of resistive sensors is relatively lower, and the production process is simpler. Therefore, in mass production, resistive pressure sensors are more economically viable.

- Sensitivity and Resolution: Resistive pressure sensors generally have higher sensitivity and higher resolution. Due to the characteristics of their working principle, resistive pressure sensors can more accurately measure pressure changes and detect smaller pressure variations. This makes resistive pressure sensors more suitable for applications requiring high-precision measurements.

- Stability and Reliability: Due to the relatively simple structure and insensitivity to environmental factors such as temperature and humidity, resistive pressure sensors exhibit higher stability and reliability. In contrast, piezoelectric pressure sensors have a more complex structure and are more sensitive to environmental conditions, making them susceptible to interference and potentially less stable and reliable in certain working environments.

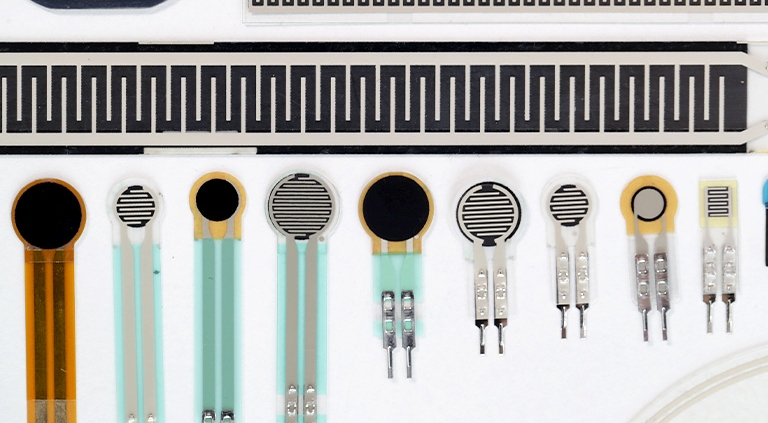

- Ease of Integration: Resistive pressure sensors typically have smaller dimensions and simpler structures, making them easier to integrate and install. This makes resistive pressure sensors more advantageous in applications with restrictions on sensor size and shape, such as in miniature devices, medical equipment, etc.

In summary, resistive pressure sensors offer advantages over piezoelectric pressure sensors in terms of cost-effectiveness, sensitivity and resolution, stability and reliability, as well as ease of integration. However, the choice of sensor type should be based on specific application scenarios and requirements to achieve optimal performance and effectiveness.