Introduction

With the acceleration of life pace and increasing work pressure, sleep quality has become a significant concern for many people. Sleep is not only essential for physical recovery but also a foundation for maintaining mental health and physiological functions. In recent years, various smart sleep monitoring devices have emerged, among which sleep monitoring pillows based on thin-film pressure sensors have become popular due to their high sensitivity and comfort.

Working Principle of Thin-Film Pressure Sensors

A thin-film pressure sensor measures surface pressure changes on an object to gather information. Its basic structure includes a sensing element, a sensing layer, and a signal processing circuit. When external pressure is applied, the sensing layer deforms, causing changes in resistance, capacitance, or inductance. These changes are converted into electrical signals by the signal processing circuit, enabling pressure measurement.

Advantages of Thin-Film Pressure Sensors in Sleep Monitoring

High Sensitivity

Thin-film pressure sensors can detect minute pressure changes, making them suitable for recording subtle body movements during sleep, such as breathing rate and turning over. These data are crucial for analyzing sleep quality.

High Comfort

Traditional sleep monitoring devices, like wristbands and headbands, may affect user comfort and, consequently, sleep quality. Thin-film pressure sensors embedded within pillows do not exert extra pressure on users, significantly enhancing the user experience.

High Durability

Made of flexible materials, thin-film pressure sensors offer good durability and longevity. Daily use, including pillow squeezing and friction, does not damage the sensors, ensuring long-term stability of monitoring data.

Functions of Sleep Monitoring Pillows with Thin-Film Pressure Sensors

Breathing Monitoring

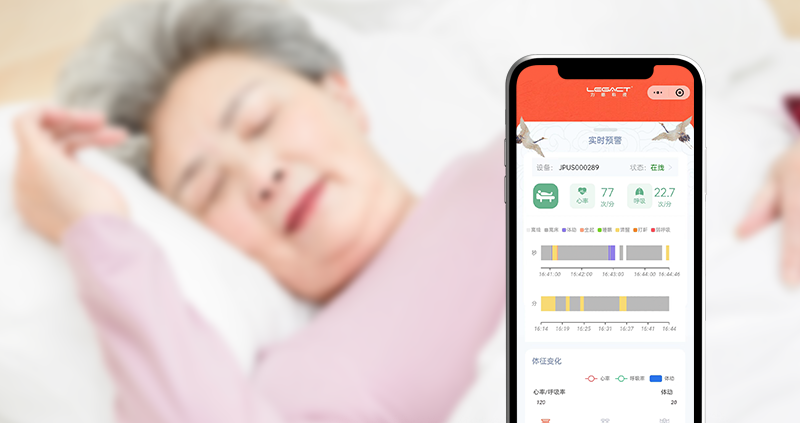

Thin-film pressure sensors allow pillows to monitor users’ breathing rates and depths in real-time. Abnormal breathing patterns, such as apnea and shallow breathing, can be detected promptly, enabling timely alerts for users or doctors to conduct further diagnosis and intervention.

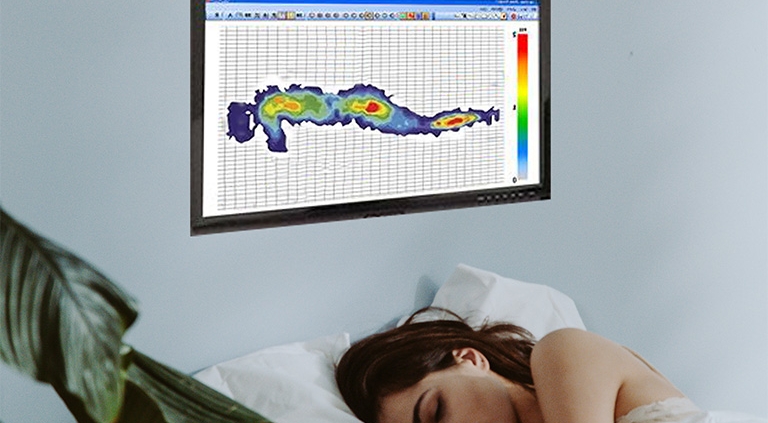

Sleep Posture Monitoring

These sensors can record the number of times users turn over and changes in sleep posture during sleep. This data helps analyze sleep habits and assists users in adjusting their sleep posture, reducing the impact of poor posture on the body, such as cervical spondylosis and back pain.

Sleep Stage Analysis

By integrating data on breathing rate, heart rate, and body movements, sleep monitoring pillows can delineate users’ sleep stages, including light sleep, deep sleep, and rapid eye movement (REM) sleep. Such detailed sleep analysis helps users understand their sleep quality and adjust their schedules accordingly.

Application Prospects

With the increasing demand for health management, sleep monitoring pillows based on thin-film pressure sensors have broad application prospects in the market. Besides personal use, hospitals, nursing homes, and other institutions can adopt this technology for patient and elderly sleep monitoring, providing more comprehensive health management services.

Conclusion

The application of thin-film pressure sensors in sleep monitoring pillows demonstrates significant potential due to their high sensitivity, comfort, and durability. In the future, as technology advances further, these pillows will offer a superior sleep experience to more people, contributing to a healthier life.

Through continuous innovation and improvement, we look forward to seeing thin-film pressure sensors play a role in more fields, contributing to human health and well-being.